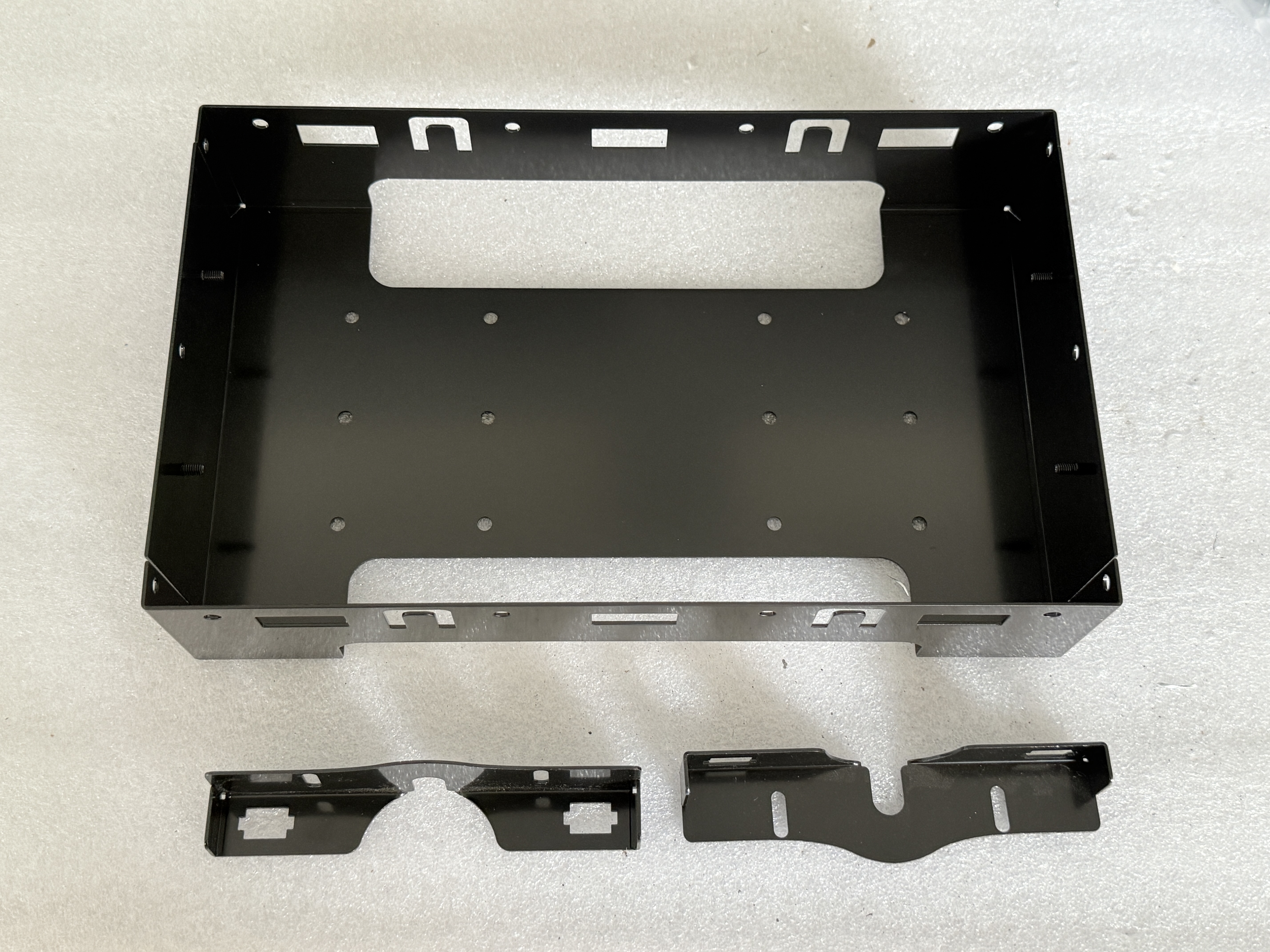

Customized sheet metal stamped shell

Category:

Product Introduction

Processing technology

Cutting: The cutting is divided into cold cutting and hot cutting according to the desired length and width.

Bending: Bending the material according to the desired shape, divided into mechanical bending and manual bending.

Stamping: The use of punching machine or die to stretch, compress, bend and shear the material, high processing precision, high production efficiency.

Welding: by means of arc welding, laser welding or resistance welding, several pieces of material are joined together to ensure structure and strength.

Application field

Stainless steel sheet metal is widely used in electronic products, automobile body, home appliance shell and other fields because of its light weight, corrosion resistance and good processing performance. For example, computer cases, mobile phones, MP3 and other electronic products.

The commonly used materials of stainless steel sheet metal include stainless steel SUS304, SPCC (cold rolled plate), etc. Stainless steel SUS304 is widely used because of its corrosion resistance, heat resistance and good mechanical properties.

Key words:

Online Consultation

Please leave your requirements and contact information, and we will contact you within one working day.

METAL FABRICATION SERVICE

We are a metal product company that integrates mold development and production, with excellent design capabilities and rich manufacturing experience.

Sheet metal parts, as a type of metal product, are carefully processed through exquisite sheet metal techniques and are mainly used in the automotive industry, electronics, and home appliances. This process covers a series of cold working operations such as shearing, stamping, cutting, compounding, bending, welding, riveting, and splicing. These processes require the use of professional equipment, such as shearing machines, CNC punching machines, laser cutting machines, bending machines, and various auxiliary equipment. During the production process, we conduct strict quality inspections to ensure that the dimensional accuracy and appearance quality of sheet metal parts meet your company's requirements.

Wall mounted TV bracket is a device specially designed to securely hang a TV on a wall, with safety and stability, and is highly favored in various fields such as home entertainment, commercial display, public information dissemination, and professional conference venues.

Welded fittings refer to connecting fittings through welding techniques to ensure their stability and sealing, and selecting appropriate welding methods based on the material, thickness, and welding requirements of the fittings. Welded pipe fittings are applied in various fields, such as various parts of TV brackets, such as bracket legs, crossbeams, connectors, etc., and are often connected structurally through hardware welded pipe fittings. We provide high-quality welding solutions for the industry with outstanding technical strength. In terms of welding equipment, we have introduced advanced laser welding machines, argon arc welding equipment, and intelligent welding robots to ensure that every product meets precise welding requirements. Choosing Jupeng Hardware means choosing professional, efficient, and reliable welding pipe fittings services.

Stamping is one of the metal plastic processing methods, also known as sheet metal stamping. It is a process method that uses molds to separate metal sheets or produce plastic deformation under pressure to obtain the desired workpiece. Stamping processing can achieve stretching, bending, punching and shearing processes using different molds. Jupeng Hardware has very professional stamping technology to ensure the production of high-quality products.

Hardware stretching parts are components that are processed into specific shapes and sizes through stretching technology, such as cylindrical, box shaped, etc. The common materials for metal stretching parts include high-strength steel, stainless steel, aluminum alloy, etc. The production process mainly includes cutting, stretching, trimming, punching, shaping and other steps. Among them, stretching is the most crucial link.