METAL FABRICATION SERVICE

We are a metal product company that integrates mold development and production, with excellent design capabilities and rich manufacturing experience.

Sheet metal parts, as a type of metal product, are carefully processed through exquisite sheet metal techniques and are mainly used in the automotive industry, electronics, and home appliances. This process covers a series of cold working operations such as shearing, stamping, cutting, compounding, bending, welding, riveting, and splicing. These processes require the use of professional equipment, such as shearing machines, CNC punching machines, laser cutting machines, bending machines, and various auxiliary equipment. During the production process, we conduct strict quality inspections to ensure that the dimensional accuracy and appearance quality of sheet metal parts meet your company's requirements.

Wall mounted TV bracket is a device specially designed to securely hang a TV on a wall, with safety and stability, and is highly favored in various fields such as home entertainment, commercial display, public information dissemination, and professional conference venues.

Welded fittings refer to connecting fittings through welding techniques to ensure their stability and sealing, and selecting appropriate welding methods based on the material, thickness, and welding requirements of the fittings. Welded pipe fittings are applied in various fields, such as various parts of TV brackets, such as bracket legs, crossbeams, connectors, etc., and are often connected structurally through hardware welded pipe fittings. We provide high-quality welding solutions for the industry with outstanding technical strength. In terms of welding equipment, we have introduced advanced laser welding machines, argon arc welding equipment, and intelligent welding robots to ensure that every product meets precise welding requirements. Choosing Jupeng Hardware means choosing professional, efficient, and reliable welding pipe fittings services.

Stamping is one of the metal plastic processing methods, also known as sheet metal stamping. It is a process method that uses molds to separate metal sheets or produce plastic deformation under pressure to obtain the desired workpiece. Stamping processing can achieve stretching, bending, punching and shearing processes using different molds. Jupeng Hardware has very professional stamping technology to ensure the production of high-quality products.

Hardware stretching parts are components that are processed into specific shapes and sizes through stretching technology, such as cylindrical, box shaped, etc. The common materials for metal stretching parts include high-strength steel, stainless steel, aluminum alloy, etc. The production process mainly includes cutting, stretching, trimming, punching, shaping and other steps. Among them, stretching is the most crucial link.

PRODUCT DISPLAY

We provide all kinds of metal stamping parts, sheet metal parts, stretching parts, welding parts, forging parts fabricate services.

About Us

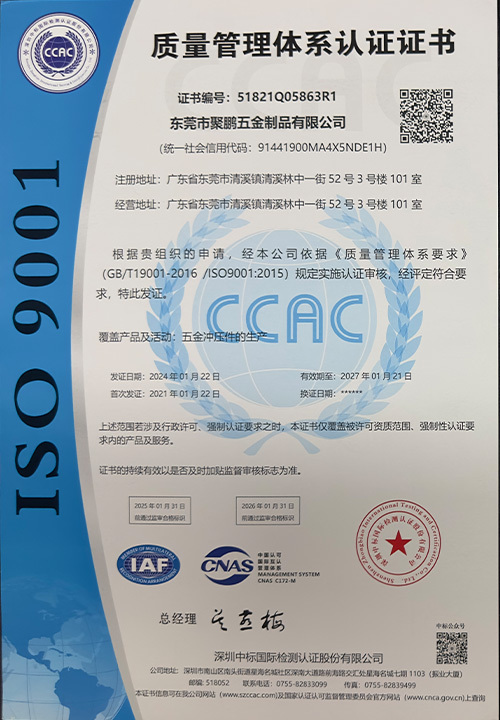

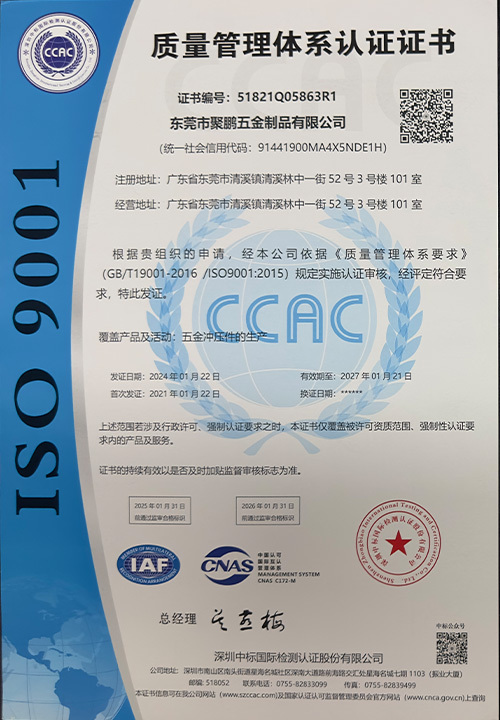

Dongguan Jupeng Hardware Products Co., Ltd. was established in 2017. It is a metal products company that integrates mold development and production. It has good design capabilities and rich manufacturing experience, and has passed the international quality system ISO9001 certification. Since its establishment, the company has continuously provided customers with the highest quality products through self-learning and its own manufacturing experience. At the same time, the company always adheres to the business philosophy of honesty, customer first, quality oriented, efficiency improvement, and continuous improvement. The company firmly believes in establishing a foothold with quality, winning profits with efficiency, catering to the market with reasonable prices, and winning your trust with service. Highly recognized by industry clients.

OUR ADVANTAGE

The company is equipped with advanced equipment both domestically and internationally, such as stamping machines, hydraulic presses, laser sheet cutting machines, laser pipe cutting machines, CNC bending machines, CNC pipe bending machines, hobbing machines, CNC lathes, welding robots, laser welding machines, carbon dioxide welding machines, argon arc welding machines, resistance welding machines, high-frequency heating machines, etc. The detection equipment includes anime projector, detection platform, tension test, salt spray test, etc.

Quality Control

Always adhere to high standards and strict requirements, pay attention to every detail to ensure the quality of the product.

Excellent Team

The company has established a high-quality composite talent team dedicated to the research and development of core technologies.

Experienced

Having years of experience in the mold development industry and strong technical strength. Having modern technological equipment.

Customized services

We can provide design and production of products with special requirements according to customer requirements.

I WANT TO LEAVE A MESSAGE

If you want to learn more about our services and products, please leave us a message